Your web browser is out of date. Update your browser for more security, speed and the best experience on this site.

Case Studies

We at BOGE supply compressed air to diverse branches of industry with the highest quality demands. From large industrial plants to small workshops; from working air to breathable air at the highest standards of quality, as required for the medical sector – efficiency, safety and precision take centre stage in each and every one of our products. Find out here about the creative solutions we’ve developed to meet our customers’ challenges – and how they benefit from working with our companies and using our innovative products.

Food and beverage industry

ABP Slaney

Improving energy efficiency

Achieving a smaller carbon footprint and lower energy bills led to an energy saving of €25,285 a year for this Irish food producer.

Cranswick Foods

Food processing industry

A processor of cooked meats has boosted efficiency, slashed downtime and improved air quality, thanks to a newly installed compressed air system.

Privatbrauerei Bolten

How Bolten is preparing for the future...

Absolutely oil-free but cost-conscious - Conception of a new compressed air system with the requirement for the highest cleanliness and maximum cost-effectiveness.

Baked Goods Industry

Efficient and high-quality compressed air...

Major bakeries and suppliers to the baked goods industry rely on it. It is all about safe food and economical production.

Oberselters Mineralbrunnen

Growth in efficiency can be controlled

Harmonising two parallel compressed air networks allows savings to be achieved: this is what happens at OberSelters, a long-standing company based in the Taunus hills of Germany.

Fanagoria Wine Cellar, Russia

Good air - great wine

The Russian Fanagoria Wine Cellar produces quality wines and brandies. The uncompromising standards of BOGE products ensure that bacteria are kept out of the wine containers.

Rotkäppchen-mumm Sparkling Wine

The finest fizz

Unpacking, cleaning, filling, labelling, packing – the Rotkäppchen-Mumm Sparkling Wine Cellar draws on BOGE’s know-how for all of the above processes.

Black Sheep Brewery

Well brewed, BOGE!

The English Black Sheep Brewery uses a compact BOGE compressed air station to bottle traditionally brewed beer. Innovative BOGE components speed up the process further.

Fonti di Vinadio Spa

Pure water from the heart of the Alps

The mineral water of Fonti di Vinadio Spa is famed for its quality. BOGE products fulfil the most exacting requirements, providing large amounts of oil-free compressed air.

FIVE:AM

100% organic, thanks to BOGE

Australian yoghurt manufacturer five:am uses exclusively organic ingredients in its products – and relies on BOGE’s 100% oil-free air for the sensitive manufacturing process.

Industrial production and metal working

Ger4tech gmbh

Reliable, energy-saving supply

BOGE compressed air provides the pneumatic drive required to ensure GER4TECH’s metal processing is successful.

James Cropper

Paper Gains

Replacing an aging compressed air system for expanding paper mill, James Cropper, was an opportunity to ensure there was sufficient capacity for growth and consistency of air supply throughout the plant.

BETTE GMBH & CO. KG

Coloured accents

Premium bathroom elements with the highest standards – the manufacturing and processing procedure at Bette requires completely clean, high-quality compressed air.

Regency Glass

Glass manufacturer reduces energy costs

When switching production to a much larger site, the company had to be sure of a reliable and uninterrupted air supply. They didn’t realise they would cut their energy costs significantly too.

Bottle Cap Manufacturer

Oil-free compressed air without oil-free compressors

One packaging manufacturer has found an alternative requiring substantially less investment – and have made impressive efficiency savings as well.

Design Factory GMBH

Classic compressed air design

Design Factory is an expert producer of sparking stainless steel surfaces. BOGE refurbished their existing system and provided them with extremely clean, oil-free compressed air.

KSI - Industrial Coatings

Coatings, coatings everywhere!

Klaus Stahl Industrielackierungen drew on BOGE’s creativity for the modernisation of their entire system – and got a tailor-made, cost-efficient solution.

Logistics and the environment

Cobalt Energy

Working in close partnership with Cobalt Energy...

...BOGE designed, supplied, installed and commissioned an integrated compressed-air system – comprising duty and stand-by screw compressors, refrigerant dryers, absorption dryers and auto drains – that met all of Cobalt’s specifications.

Xylem Water Solution

A clean solution

Xylem must flush and ventilate its pipes regularly to avoid odours and bacteria build-up. BOGE compressors supply the power that makes this possible, all over the world.

Idam Moncofa

From the sea to the cup

IDAM Moncofa processes its seawater in sunny Spain. Their desalination system uses BOGE compressed air to ensure sufficient water supply for people and agriculture.

Spedition Rinnen

Getting them on the road …

… that's what BOGE has done with the vehicle fleet of international haulier Spedition Rinnen. Its compressed air system has become more efficient and reliable thanks to the new dust-free environment and higher-level control on site.

Recycling

Alunova Recycling GMBH

Keeping the belt moving

Intelligent BOGE controls ensure the faultless interaction of all components involved in Alunova’s aluminium recycling operations, saving large amounts on energy.

Tönsmeier Group

The crucial milliseconds

BOGE compressed air aids the Tönsmeier group in the sorting of recyclable resources during plastic recycling. The system’s idle time and maintenance requirements are minimal.

Bürck Rohstoffhandel & Recycling

A crystal-cut case

Bürck Rohstoffhandel & Recycling uses BOGE compressors for glass recycling. Long-term efficiency and reliability are guaranteed, even under tough operating conditions.

PD Energy

A hot number

PD energy relies on dry, particle-free BOGE compressed air to carry out their thermal waste management. The high quality of the air protects sensitive components.

Veolia Environmental Services

Keeping things tidy

Veolia sorts 85,000 tons of recyclable waste every year. A frequency-controlled BOGE piston compressor supplies the required compressed air at the highest levels of precision.

Other sectors

DELCOTEX

Focusing on energy efficiency

For DELCOTEX, European market leader for technical textiles of different kinds, oil-free compressed air is essential: weaving machines, for example, use compressed air to propel threads from one selvedge to the other at a speed of 300 km/h.

Barber Institute of Fine Arts

Compressor failure and rising costs no longer a worry

Around £3,500 saved annually on compressor replacements, and over £1,000 on energy consumption for the Barber Institute of Fine Arts.

Saalfelder Wäscherei GmbH

To keep the washing clean...

...Saalfeld laundry relies on BOGE. Frequency-controlled compressors, modern control, heat recovery - for optimum load coverage with the best efficiency values.

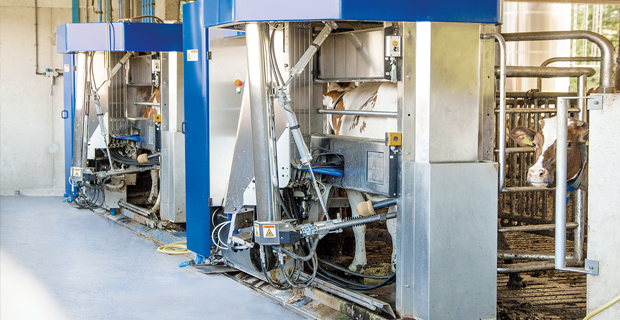

Herwig Taute

With milking, nothing is more important than hygiene …

Configuration of automatic milking systems with super-silent, absolutely oil-free scroll compressors from BOGE.

Vorbuchner GMBH & CO KG

Light gas, heavy job

…in cooperation with Vorbuchner GmbH & Co KG, BOGE specialists developed a prototype that compresses helium efficiently and safely.