Your web browser is out of date. Update your browser for more security, speed and the best experience on this site.

- Home

- News

- Press Information

- Reducing energy costs by 50 per cent, thanks to efficient compressed air management

Reducing energy costs by 50 per cent, thanks to efficient compressed air management

Thursday, November 28. 2024

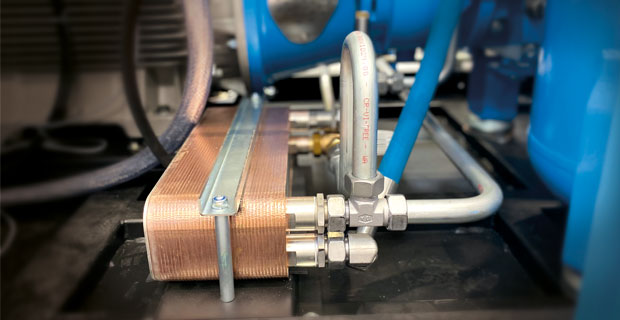

With extensive measures, BOGE not only helps its partners to lower operating costs but also makes an active contribution to better sustainability and climate protection. (Source: BOGE)

Protecting budgets and the environment with sustainable compressed air generation: If industrial companies adjust the right elements, they will be rewarded with high savings potential and improved economy. This is how companies can halve their required energy requirements for compressed air generation, for example. This protects resources and lowers operating costs. Using smart tools provided by BOGE, companies can identify and use this potential.

Regular maintenance is indispensable for the efficient use of compressed air. After all, wear on seals and hoses can have significant financial consequences. Leaks are among the major and most common causes of energy losses in compressed air systems. Without regular maintenance, they will often remain undetected, wasting up to 50 per cent of a system’s energy. To prevent this, BOGE has integrated a leak monitor in the control of its compressors. “The monitor records leaks during downtimes, thus allowing precise identification and rapid elimination of energy losses. This means that significant costs can be saved with minimal effort”, explains Frank Hilbrink, BOGE Product Manager.

Another important area where companies can lower energy costs, and can therefore be more economical, is heat recovery. Up to 94 per cent of energy used during compressed air generation can be re-used as heat. In this process, BOGE diverts the waste heat from the compression process, specific to each compressor. It can then be used to heat rooms or water, for example. Compressors manufactured by others can also be retrofitted with BOGE’s heath recovery system. The average payback period is merely four months.

Up to 94 per cent of energy used during compressed air generation can be re-used as heat.

Smart control optimises compressor utilisation

An interlocking control, such as the BOGE airtelligence provis 3, makes the entire compressed air management efficient and adaptable. The intelligent control solution ensures the ideal utilisation of compressed air systems. The software integrates an unlimited number of components and, based on requirement, works out the perfect compressor configuration for a specific time during operation. The smart tool is therefore particularly suitable for highly fluctuating compressed air requirements and mixed compressor combinations. Additionally, the airtelligence provis 3 continuously optimises energy consumption: a reduction by merely 1 bar saves as much as 10 per cent in energy costs.

Furthermore, the interlocking control helps with energy audits. Since 2015, the German Federal Government has obliged companies to perform regular energy audits or to introduce an energy management system in accordance with ISO 50001. Smart software solutions, like those provided by BOGE, allow the integration of relevant data sources without recording actual usage data. The analysis of this data helps to identify energy savings potential and to meet the requirements of the certification process. If a company receives its certification, it will benefit from certain tax relief. With these measures, BOGE not only helps its partners to lower operating costs but also makes an active contribution with them to better sustainability and climate protection.

The airtelligence provis 3 continuously optimises energy consumption: a reduction by merely 1 bar saves as much as 10 per cent in energy costs.

About BOGE Compressors

With more than 115 years of experience, BOGE KOMPRESSOREN Otto Boge GmbH & Co. KG is one of the oldest manufacturers of compressors and compressed air systems in Germany. The company is one of the market leaders. Be it screw compressors, piston compressors, scroll compressors or turbo compressors, complete systems or individual machines - BOGE meets the most diverse requirements and the highest demands. With precision and dedication to quality. The internationally active family business employs around 750 people and is managed by Olaf Hoppe and Michael Rommelmann. BOGE offers its international customers comprehensive service through numerous sales offices and subsidiaries. The company supplies its products and systems to more than 120 countries worldwide.