Your web browser is out of date. Update your browser for more security, speed and the best experience on this site.

Turbo compressors

BOGE’s new T series has recognised the signs of the times: it saves resources and energy, doesn’t use a drop of oil and reduces noise levels to a minimum, despite its high speed. Whether high or low pressures are required – low-wear turbo technology sets completely new standards for efficiency and cost savings. The extremely small footprint is also a bonus of the superior drive concept. The result: oil-free compressed air with minimal space requirements ... and surprisingly cost-effective!

More energy with fewer raw materials

The main advantages at a glance

- Superior drive concept

- Very high energy density

- No oil or lubricant whatsoever

- Extremely small footprint

- Low maintenance and operating costs

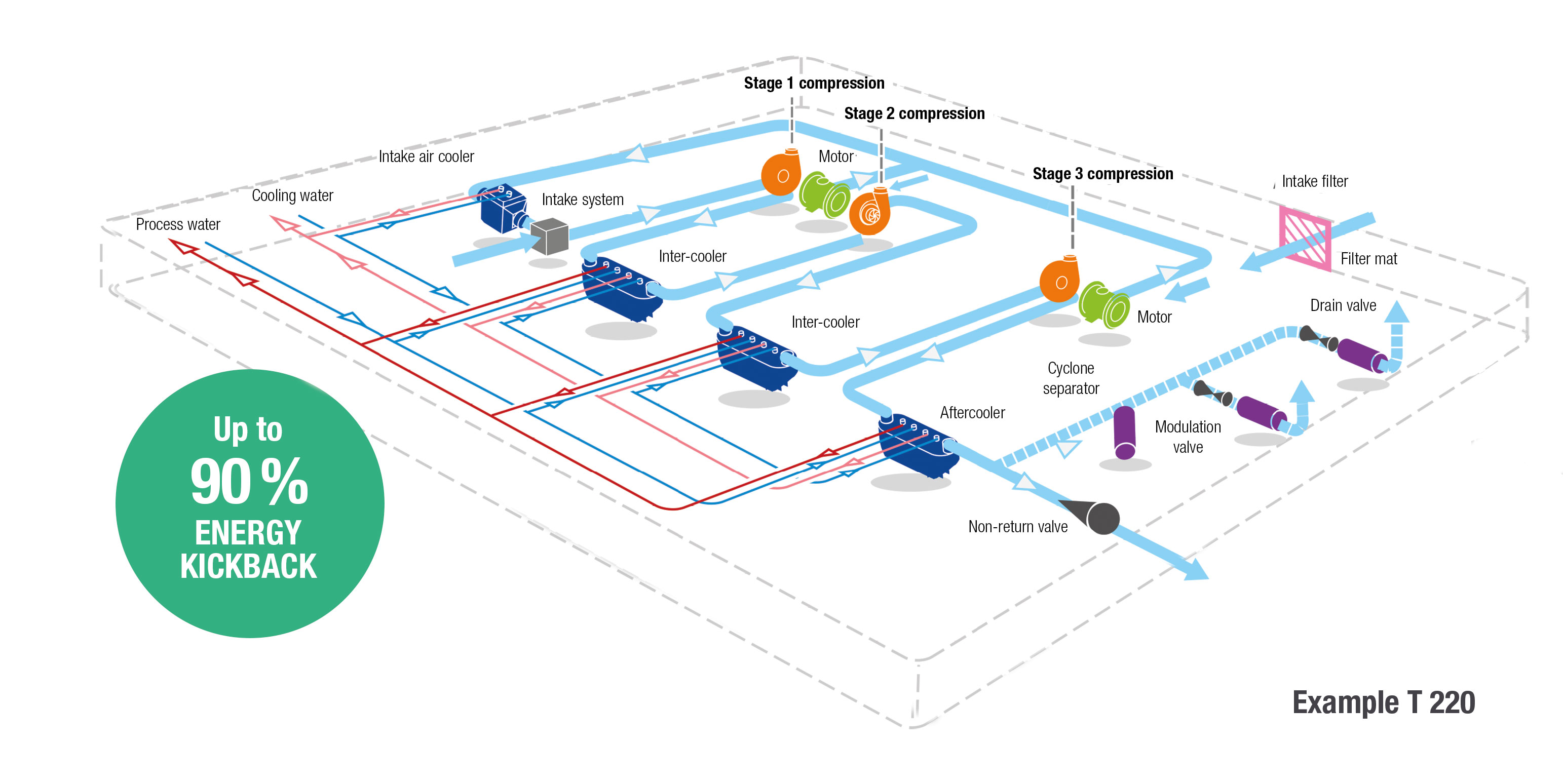

- Efficient heat recovery

- Long service life

- Significantly lower sound pressure level

A smart concept in all respects

Increased efficiency? Easily!

With their smart design, these T series models get to the heart of the downsizing principle: compared with conventional screw compressors, they have been reduced to half the size and a third of the weight.

The design principle

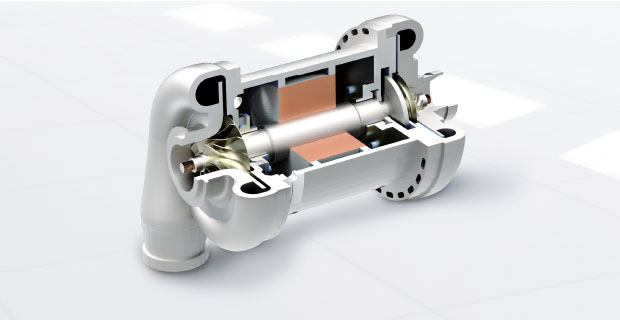

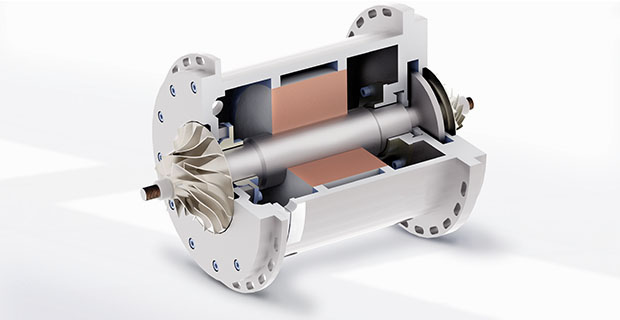

The combination of a permanent magnet motor and air-cushioned drive on which the impellers are located really bring out the clever design of this oil-free compression principle.

High speed by conviction

Permanent magnet motors, as used in the T series, have several advantages: they take up little space and allow high speeds beyond 100,000 rpm. They are also characterised by their very high energy density.

Scores of benefits, thanks to air cushioning

To provide maximum speed, the air-cushioned shaft needs neither external energy nor any operating material other than air – it simply works all the time, even in the event of a power cut.

Versatility as a logical consequence

Put simply, the main difference between the high pressure range models (T) and the low pressure range models (LPT) is the number of airends used. This means maximum flexibility during execution.

Oil-free and sustainable, thanks to heat recovery

Smart engineering for high and low pressures

The impressive advances made by turbo technology in the area of the production of completely oil-free compressed air are evident in the high pressure range beyond 100,000 rpm as well as in the low pressure range. Every design detail has been revised, from the particularly maintenance-friendly set-up to the operation of the T series compressors, saving energy and resources.

T 220

A turbo for the high pressure range

The T series is setting new standards with its drive principle – when it comes to energy and maintenance requirements as well as with its footprint, weight and sound pressure.

LPT 150

A turbo for the low pressure range

High speeds are also good for low pressures: the LPT will win you over with significantly greater efficiency compared with a screw compressor.

Optimised & tailor-made for all requirements

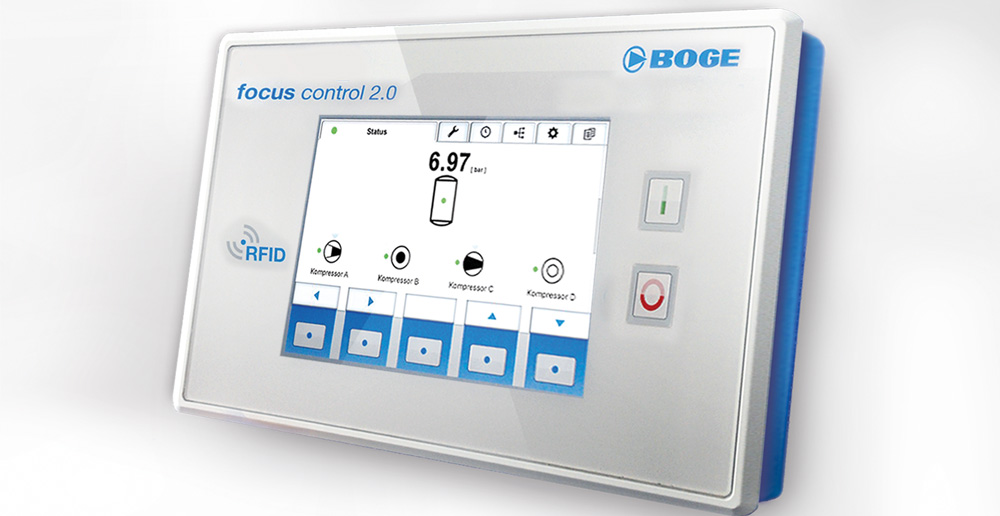

Control at the level of your choice

Optimising and remotely monitoring energy consumption using the focus control 2.0 machine control and the BOGE connect “Smart Service” tool.

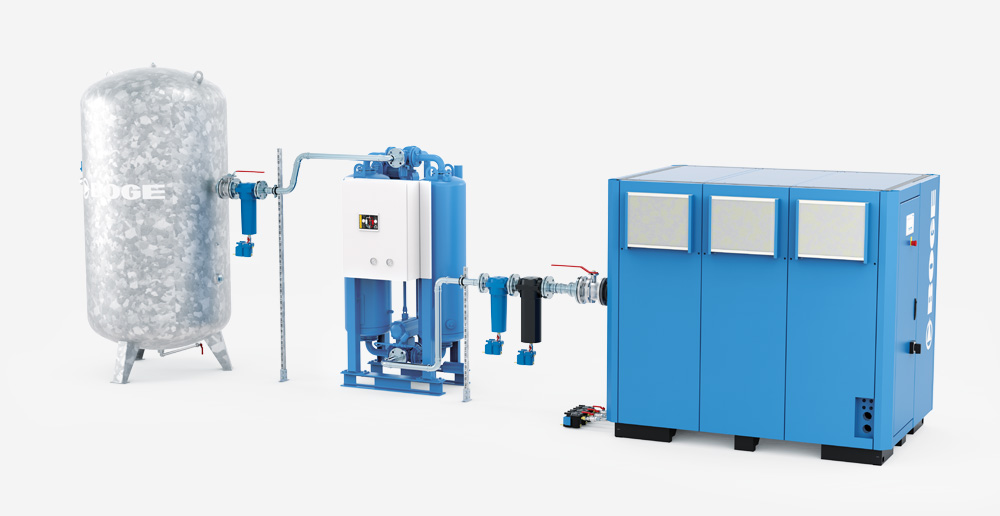

Personalised system solution for any requirement

With our comprehensive range of high-quality treatment products, any conceivable area of application can be personalised to suit you.

Tailor-made service: Always there for you

- Extremely maintenance-friendly

- Refurbishing programme for the T series

- Technical support around the clock

- Specialist seminars (BOGE Druckluft-AIRcademy)

So you can take care of your core business without worrying, we will ensure the smooth running of your compressed air system. From technical support in

emergencies to customised maintenance agreements and diagnostic tools for effective compressed air management – our services meet your specific needs precisely. Our warranty for motor/compressor units is new.

Do you have any further questions?

We will be pleased to explain the specific advantages of this innovative technology to you. Please do not hesitate to contact us.