Your web browser is out of date. Update your browser for more security, speed and the best experience on this site.

The new milestone

With the new S-4 models the fourth generation of the popular S-series is already starting out to encourage and spearhead industrial progress. This generation not only makes it possible to achieve a significant breakthrough with saving energy, but also takes sound insulation and ease of maintenance to an entirely new level. The international claim made with the launch is equally confident: "Designed to take the lead". We are in fact looking at a fundamentally new design here. And it is this very approach – constantly scrutinising tried and tested technologies – that characterises BOGE's long-standing family business, which is now, fittingly, also in the fourth generation.

Both representing the fourth generation of their family

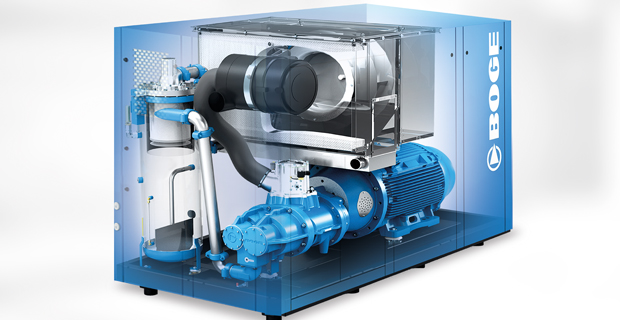

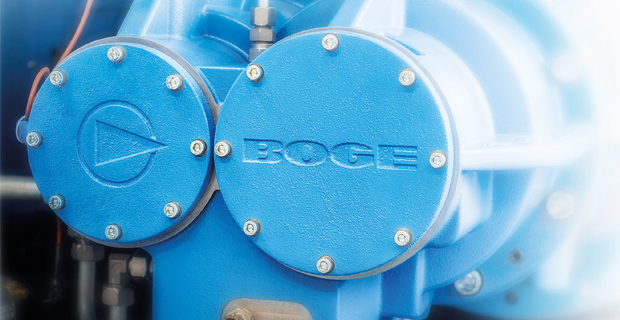

- BOGE "IntegrateDrive" airend

Enclosed, low losses and virtually maintenance-free with optimum efficiency - Sound-optimised cooling air duct

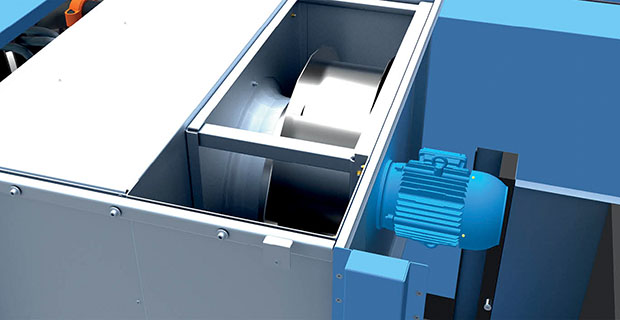

Audible success thanks to specific insulation measures at the deflection points - Low-speed radial fan

Reduces noise and energy costs – optionally available with speed control - Elastic "SilentMount" suspension

All components are secured to the base frame with elastic mountings to ensure isolation from vibrations - Maintenance-friendly design based on the easy access principle

Access limited to 2 sides, all components readily accessible - Innovative separation technology for safe, convenient cartridge replacement

New swivel mechanism for the cover makes changing cartridges faster and banishes the risk of accidents

Frank Hilbrink, Team Leader Product Market Management

No other screw compressor on the market can be serviced so easily.

Taking efficiency to a new level

MINIMAL POWER CONSUMPTION, EXTREMELY SHORT DOWNTIMES, very simple maintenance and a long life expectancy – the BOGE S-4 series has what it takes to outshine all screw compressors in the same class. From the outset the new models offer the most efficient screw compressors in their specific segment. At the heart of every S-4 is the BOGE "IntegrateDrive" airend, which was developed in-house. This features robust integrated gears or direct drive with speed control.

The latest milestone from BOGE

The design principle of the S-4

The S-4 series represents a significant breakthrough in terms of energy consumption, noise emissions and ease of maintenance.

Efficiency-optimised airend

The airend with integrated, fully enclosed gears reduces internal pressure losses as well as energy consumption and noise levels.

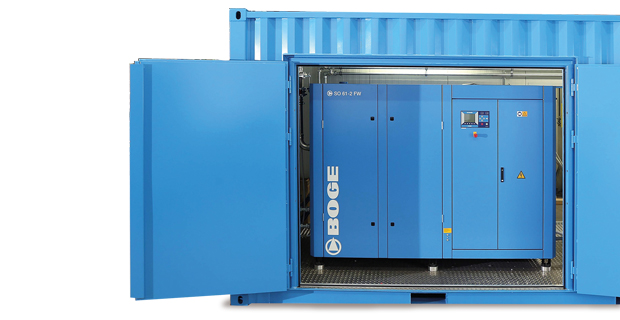

Tailored exactly to your requirements

A container solution with room for everything: compressors, processing and control technology. Thanks to its compact design, models from the S-4 series are just perfect for this.

Quieter for greater flexibility

Every design feature has been developed with a view to maximum noise reduction. The result? The quietest screw compressors in their class.

Everything under control

The focus control 2.0 controls up to four connected compressors with base load switching as required and monitors all inlet and final pressures.

Practical by nature – particularly when it comes to maintenance

ALL SOUND-INSULATING PANELS ON THE S-4 CAN BE REMOVED FOR FAST ACCESS IN NEXT TO NO TIME. Regular maintenance work can be performed from just two sides: Changing the oil and separation cartridge takes place at the front of the machine, likewise the suction regulator, minimum pressure valve and oil regulator. Only the oil filter, the air filter and the primary intake air filter are changed from the side.

Thinking on a larger scale, down to the smallest detail

The easy access principle

Multiple benefits from the radial fan

Innovative oil separation technology

Accident-proof swivel mechanism

Elastic "SilentMount" suspension

Victaulic© couplings

BOGE S-4 will also impress in the most challenging environments

Paint shops

Guaranteeing a continuous supply of compressed air, the new BOGE S-4 range is ideal for example when using spray guns, ensuring here a reliable and uniform application of paints and varnishes.

Mining

The S-4 is in its element in the mining industry, where screw compressors need to be especially safe and reliable when faced with adverse conditions. It scores here with extremely short downtimes, very simple maintenance and a long life expectancy

Metalworking

Compressed air that is clean and dry is essential for the metalworking sector. BOGE's new S-4 series supplies high-quality air, as required e.g. for treating and processing stainless steel or for laser cutting.

Oil, gas and chemicals industry

When it comes to the sensitive production processes used in the oil and gas sectors, the quality of compressed air must be just as flawless as in the chemicals industry, where toxic, corrosive and unstable substances are frequently involved in manufacture. A clear case for the S-4.